International Six Sigma Council (ISSC) Asia Quality

Management (AQM) Symposium is the flagship event and held on 10th

May 2018. The symposium theme is

“Quality Growth beyond Excellence through Innovation”. The symposium scope spans from the

application of QFD, LEAN, TRIZ and Extenics (可拓學) to

the exploration of enormous opportunities though Innovation. Before the symposium, all speaker took a

group photo.

(Left: Dr. Jason Kong (Vice-Chairman/Marketing, ISSC), Dr. Catherine

Chan, Dr. CO Chan (President, ISSC), Ms. Ada YS Fung BBS JP (previous Deputy

Director of Housing (Development & Construction), Dr. Victor Lo, Dr. Wei

Pan and I)

In the beginning, Dr. CO Chan (President, ISSC) gave

an opening remarks. He said ISSC had

servicing quality field for 12 years. He

briefed the success of WhatsApp that innovation could be started from small

things. In 2014, Facebook acquired WhatsApp for US$19 billion!

Ms. Ada YS Fung BBS JP (Former Deputy Director of

Housing (Development & Construction) was the keynote speaker and her topic

named “Quality is Not an Act; It is a Habit”.

Firstly, she shared the Housing Authority (HA) vision, mission and core

values. They used people-centric

approach with competent, dedicated and performance-oriented team.

Then Ms. Ada Fung discussed their team’s challenges included External parties, Employer and Contractor. She found that Quality People, Quality System and Quality Product were client need. Therefore, HA had many different program to focus on people management.

And then she said they

needed systems for management including ISO 9001, ISO 14001, HKQAA CSR Index

(ISO 26000), ISO 50001 and Building Materials Control System (ISO 31000) and

EFQM, etc. Ms. Ada Fung mentioned the European

Foundation for Quality Management (EFQM) was focused on people. After implemented such systems and continuous

improvement, their customer satisfaction index increased from 70% to >90%

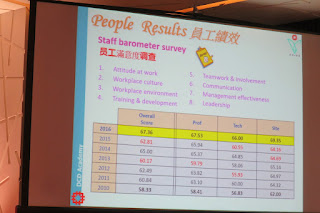

recently. One of activities reflected HA

focused on staff that was Staff Barometer Survey, HA based on the people result

for internal improvement.

After that Ms. Ada Fung

briefed some cases in which solved problems by Innovation. One of cases named the 2nd

Generation Acoustic Balcony which installed in Wah Ha Estate at Chai Wan.

Ms. Ada Fung also mentioned

how they implemented their idea. Firstly, they had R&D Steering Committee

with objectives included cost effectiveness, quality through innovation, and quality

through sustainability for evaluating effectiveness of individual R&D

projects. For new technology

implementation, their collaboration round table involved HA, Contractor,

Academia, Consultant, Manufacturer, Regulator, Sub-Contractor, Supplier and

Laboratory. Then she introduced the 5

stages of Implementation of R&D: 1. Exploration, 2. Piloting, 3.

Monitoring, 4. Reviewing, and 5. Mass Application.

Finally, Ms. Ada Fung

introduced the Building Information Modeling (BIM) in full design and construction

cycle. Lastly, she shared her dream to us that was to integrate the BIM and Geographic

Information System (GIS) since 2011.

Recently, Autodesk and Esri announced the start a new relationship to

build a bridge between BIM and GIS mapping technology on 15 Nov 2017.

After the keynote speech,

all guests received trophy and took a group photo.

The second speaker was Dr. Catherine Chan (Founder

& President, Hong Kong QFD Association) and her speech was “The Way QFD

Manages and Develops Innovation”. Dr.

Chan mentioned seeking ideas for new products and new service using QFD.

Firstly, Dr. Catherine Chan briefed that Enterprises

were busy with seeking for new ideas and finding ways for cutting costs. Innovation is required for “New &

Improved”. So that she raised a concept that included Knowledge, Innovation and

Sustain to finding new things. The

fundamentals QFD Innovation were from “Knowledge Sharing &

Creation” and “Inspire Ideas & Formulate”.

Then Dr. Catherine Chan

introduced Nonaka’s SECI Model which combined with QFD related to knowledge

management.

After that Dr. Chan briefed

how QFD for innovation through the following points:

1. Gain inspiration from exploring customers’ needs

2. Highlight areas for innovation through quality

planning

3. Support innovation and carefully adopt suggestions

Lastly, Dr. Chan concluded

practicing QFD could promote the inspiration of new ideas.

Dr. Victor Lo (Honorary Lecturer, IMSE Dept., HKU) was

the third speaker and his presentation title was “The Development of the

Innovative Quality Improvement (IQI) model with Design thinking & TRIZ”. He said the first wave was Quality and the

coming wave was Innovation. Innovation

is the mega trend.

Then Dr. Victor Lo quoted

McKinsey & Company’s 2015 survey on innovation and creativity that was

found 84% global executives believed innovation was very important but only 6%

of executives were happy about employee innovation performance. Based on Lego foundation study, human

creative thinking scores would be decrease by age and almost to be zero over 25

years old.

After that Dr. Victor Lo

briefed the TRIZ methodology to solve industry problems using 40 inventive

principles. He raised one of 40

principles as example that was IP 13 – Inversion. And then he also shared his

dream to develop a method could be universally applicable.

Dr. Lo then summarized his

Innovation Quality Improvement (IQI) model and briefed the innovation definition

included “Need → New + Function → Value” (需新用值) and PKIR

Model (問知創行) where P – Problem identification, K – Knowledge

acquisition, I – Ideation and R – Realization.

Finally, Dr. Victor Lo said

“Innovation is a skill that can be learnt and it is a process that can be

managed.” He also showed the overall flow chart for promoting the innovation

and against psychological inertia.

At the end, he employed one

of TRIZ tools named “Nine Window” to find out “What and How to Innovation?”

Tea Break

During the break, I took a

photo with quality friends.

(Left: I, Mr. Harry Li (President, IISE (HK)) and Mr. Henry Soo

(Director of Operation, ISCEA.HK))

(Left: Dr. Jason Kong (Vice-Chairman/Marketing, ISSC) and Mr. Solomon

Poon (VP, Quality and Operations Excellence, Greater China Organization,

Sanmina))

I (Dr. Lotto Lai - Chairman, HKSQ) was the fourth speaker and my

presentation entitled “Hong Kong Quality Innovation Way – Innovation Culture

based on Extenics (可拓學)”. My presentation contents included

introduction of HKSQ, key strategy in China and Hong Kong, Extenics, Three Creative

Methodology under Extenics and Integrated USA, RUSSIA & CHINA innovation

methodology, as well as, Innovation Management System.

Firstly, I briefed the HKSQ

history since 1986. We were world

partner with America Society for Quality (ASQ) and founding member of Asia

Network for Quality (ANQ), as well as, the founding member of World Alliance

for Chinese Quality (WACQ). Our flagship

annual event was HKSQ Company-based Student Project Competition and

participants in ASQ Conference, ANQ Congress and WACQ Summit.

Then I briefed some key

strategies such as One Belt One Road, Made in China 2025, and “Guangdong-Hong

Kong-Macao Great Bay Area”, as well as, “Hong Kong-Shenzhen Innovation and

Technology Park in the Lok Ma Chau Loop” and “Reindustrialization in Hong

Kong”. One of China new strategies was

related to my topic was “New generation of AI development plan”.

After that I explained the

definition of Quality Innovation and briefed the history of Quality and

Innovation tools development, as well as, matching with four industrial

revolution. Per Prof. Cai Wen, the 1st

industrial revolution was extension of Arm (power), the 2nd industrial

revolution caused by extension of Leg, Ear & Eye. The 3rd industrial

revolution was computer power and IT that extension of part of human

brain. The coming 4th industrial

revolution was from AI power that extension of human intelligence.

I introduced Prof. Cai Wen (founder of “Extenics”) who studied the law, theory and method for dealing with incompatible problems since 1976. The birth of “Extenics” was in 1983 based on his first paper of this topic named “Extension Set and Incompatible Problem”. And then I briefed the fundamental theory and started from Basic-element in which separated into 3 key elements and they were Object, Characteristic and Value. Nevertheless, I introduced the Extension Four Step Method named Model, Extension, Transformation and Selection (METS).

In METS, I explained more

in Extension that included two methods for enhancing your thinking. One was Extensible Analysis and the other was

Conjugate Analysis. In Extensible

Analysis, it included four methods named “Divergence”, “Correlative”, “Implication”

and “Opening-up”. In Conjugate Analysis,

all things were considered into four dimensions and they were Nonmaterial Part

and Material Part (Physical), Soft Part and

Hard Part (Systematic), Latent Part and Apparent Part (Dynamic), as well as,

Negative Part and Positive Part (Antithetic).

First, Second and Third Creative Methods based on “Extenics” was

introduced and discussed. The First

Creative Method (無中生有) started from

customer needs and solve the contradiction of unsatisfied needs. It needed to

use the Conjugate Need analysis. The Second

Creative Method (有中求變) started from the

existing product and extending their function or other characteristic to get

the new product. It usually employed

Extensible Analysis. The Third Creative

Method (改缺成優) started from the

default of the existing product to improve it to be new product. It needed to

use METS method to solve the problem.

Finally, I demonstrated

some studies on “Extenics” and briefed industrial case such as Baby First

Education Group was the first Hong Kong Company trained and employed “Extenics”

Lastly, the integration of Extenics, TRIZ and

Innovation Culture together for holistic approach was proposed and integrated

into Quality Innovation Management System based on ISO 9001:2015 and CEN/TS

16555-1 and its series was discussed, as well as, introduced the coming ISO

standard ISO 50501 Innovation Management System. And then I quoted Prof. Cai Wen statement as

conclusion that “Let’s develop and promote the China original discipline

“Extenics” together.”

The last speaker was Dr. Wei Pan (Executive Director,

Center for Innovation in Construction & Infrastructure Development, HKU)

and his topic entitled “Enhancing Construction Productivity and Quality through

Innovation”. Dr. Wei Pan briefed his topic contents

included rethinking theory, examining productivity and quality, challenges to

Hong Kong, and shared some examples of innovations.

In the beginning, Dr. Wei Pan briefed the Construction

Productivity in which had four-fold theoretical approach and they were “Ontology”(本體論),

“Epistemology”(認識論), “Methodology”(方法論)

and “Axiology”(價值論).

Then Dr. Wei Pan explained

that construction productivity could be regarded as a measure of outputs that

were obtained by a combination of inputs. Those output could be tangible and

intangible. The calculation showed as

follows:

Construction Productivity =

Optimum Outputs / Optimum Inputs

= Less construction time

and cost + Intangible outcomes + Long-term impacts.

And then Dr. Wei Pan briefed

the construction productivity based on Epistemology.

After that Dr. Wei Pan

mentioned the methodology such as evaluation framework using Total Factor

Productivity (TFP) which was defined as the ratio of outputs (construction

output) to all inputs (intermediate, labor and capital, etc.) used for

producing the outputs. He also

introduced productivity measurement models from Singapore, US and UK.

Socio-technical values

construction productivity belonged in Axiology.

It included Contractor, Project Manager, Project Owner, Site Labor and

End-user, as well as, other stakeholders.

Finally, Dr. Wei Pan shared

some example about Consraint, Strategy and Existing Measures to us. One of

their project named “Lean Construction for Improving Productivity in the Hong

Kong Construction Industry” was discussed.

Lean Construction aimed lean production, reducing waste and minimizing

resources.

At the end, Dr. Wei Pan

summarized his talk in the following points:

1. Construction productivity and quality are systems

concepts

2. Systems strategies are required for productivity

enhancement

3. Lean construction is an important approach

4. Modular Integrated Construction (MiC) is a

disruptively innovation Solution.

In panel discussion, Dr. CO

Chan (President, ISSC) was chair and all speakers discussed about participants

questions. Our discussion topic included

education on innovation, implementation and promotion of innovation, as well

as, innovation culture.

After the symposium, we

went to the venue of ISSC annual dinner. I met many friend here and took some

photo for memory.

(Left: Dr. Sammy Wan (Past

President, IISE(HK)) and I)

HKSQ Representatives

(Left: Dr. Catherine Chan, I and Dr. Aaron Tong)

Sanmina Team

(Left: Mr. William Chui (VP), Dr. CO Chan (ISSC), I (HKSQ), Mr. Solomon Poon

(VP – Quality and Operation Excellence) and Mr. Edward Law (Director,

Operations))

GP team

(Left: Dr. Sammy Wan, Mr. Cheung (Knowledge Management, GP), Mr. Larry

Lee (Customer Services & Compliance Quality Manager), Dr. Aaron Tong, I and

Mr. Harry Li (President, IISE (HK))

(Left: Mr. Henry Soo (Director of Operation, ISCEA.HK), I and Ms. Sarah

Mak (Regional Executive Director of the Quality Management Division of ASQ))

Before the annual dinner, Dr. Jason Kong (Vice-Chairman/Marketing, ISSC) presented certificates to all supporting organization. I represented Hong Kong Society for Quality (HKSQ) to receive the certificate.

In the beginning of annual

dinner, Dr.

CO Chan (President, ISSC) gave a welcome speech. He reviewed the vision, mission and value of

ISSC, as well as quality related activities in the past year.

Dr. Sammy Wan (Past

President, IISE(HK)) was the keynote speaker of ISSC Annual Dinner 2018 and his

presentation topic entitled “Applying Lean Thinking in Construction Industry to

Build for the Future”.

Firstly, he reviewed the

efficiency of construction industry in USA and found that was declining

compared with other industry. Then Dr. Wan mentioned the lean thinking in

construction because of many wastes using schedule to push for work.

With extremely poor

coordination and communication, a large amount of pending works could escalate

after starting work. So inadequate

preconditions could arise conflicts at works and design changes or errors were

primary sources of rework that was key production waste. Dr. Wan stated to use Lean and BIM together

that had synergy effects to save cost and reduce waste and increase efficiencies.

At the end, Dr. Sammy Wan

concluded Lean thinking in the industry was crucial. And he predicted that BIM and Digitalization

was the key to change the industry very soon and very dramatically.

Dr. CO Chan (President, ISSC) presented the trophy to Dr. Sammy Wan.

All guests in table 1 &

2 took a group photo.

ISSC representatives had a toast

to all guests and dinner started.

During the lucky draw

session, Dr. Aaron Tong presented a gift to Dr. Catherine Chan. She was so lucky!

Amazing that I was won the

other lucky draw and Mr. Solomon Poon gave the gift to me.

It was a very successful

Symposium and Annual Dinner. Before

left, we took a photo with Dr. CO Chan and Dr. Jason Kong to express our appreciation

for their invitation.

Reference:

It is my nine times to join ISSC annual dinner since

2010. I would like to summarize ISSC

annual night that I participated and recorded below:

20170518: ISSC 11th Anniversary and Annual Dinner 2017

- https://qualityalchemist.blogspot.hk/2017/05/issc-11th-anniversary-and-annual-dinner.html#more

20160623: ISSC 10th Anniversary and Annual Dinner 2016

- https://qualityalchemist.blogspot.hk/2016/06/issc-10th-anniversary-and-annual-dinner.html

20150611: AQBPA Award Ceremony Cum ISSC Annual Dinner

2015 - http://qualityalchemist.blogspot.hk/2015/06/aqbpa-award-ceremony-cum-issc-annual.html

20140522: ISSC Six Sigma Networking Night 2014 - http://qualityalchemist.blogspot.hk/2014/05/issc-six-sigma-networking-night-2013.html

20130508: ISSC Six Sigma Networking Night 2013 - http://qualityalchemist.blogspot.hk/2013/05/issc-six-sigma-networking-night-2013_8.html

20120510: ISSC Six Sigma Networking Night 2012 - http://qualityalchemist.blogspot.hk/2012/05/issc-six-sigma-networking-night-2012.html

20110505: ISSC Six Sigma Networking Night 2011 - http://qualityalchemist.blogspot.hk/2011/05/issc-six-sigma-networking-night-2011.html

20100505: ISSC Six Sigma Networking Dinner - http://qualityalchemist.blogspot.hk/2010/05/issc-six-sigma-networking-dinner.html

沒有留言:

發佈留言